Grinding wheels are an essential tool used in the automobile industry for various applications, including grinding, cutting, and polishing of different components. These wheels are made from various abrasive materials such as aluminum oxide, silicon carbide, and diamond, and their properties are customized according to the specific application requirements.

In the automobile industry, grinding wheels are used to grind and shape engine parts, gears, brake pads, and other components. For example, crankshafts and camshafts are ground using specialized grinding wheels to achieve precise shapes and dimensions.

The choice of grinding wheel for a particular application depends on several factors, such as the material being ground, the required surface finish, and the amount of material to be removed. For instance, a grinding wheel with a coarser grit is used for rough grinding, while a finer grit is used for finishing.

Additionally, grinding wheels are designed to withstand high temperatures and pressures generated during the grinding process.

They are also designed to be durable and long-lasting, reducing the need for frequent replacements.

CBN (cubic boron nitride) grinding wheels are widely used in the automobile industry for grinding and shaping a variety of materials including hardened steels, cast iron, and superalloys. CBN is a synthetic material with hardness and wear resistance similar to that of diamond, making it an excellent choice for grinding applications.

The automobile industry demands high precision and accuracy in the manufacturing of components, and CBN grinding wheels are well-suited to meet these requirements. They are able to maintain their shape and sharpness over long periods of use, resulting in consistent and repeatable grinding performance. This is important for achieving tight tolerances and smooth surface finishes. CBN grinding wheels are also effective in reducing grinding time and increasing productivity, as they can operate at higher speeds and remove material more efficiently than traditional grinding wheels.

Cylindrical Vitrified bond CBN grinding wheels

Application: Crankshaft and Camshaft

Work-pieces material:

Cast iron: Chilled cast iron, nodular cast iron, grey cast iron, alloy cast iron etc.

Steel: 20Cr, GCr15, CF53, 45# steel, 55# steel, 80B high carbon steel etc.

Internal Vitrified bond CBN grinding wheels

Application:

Hydraulic tappet of automobile motor/Pump stator of automobile / Roller, cylinder,

flange cover of air-condition compressor / CV J ball-cage, inner and outer raceway.

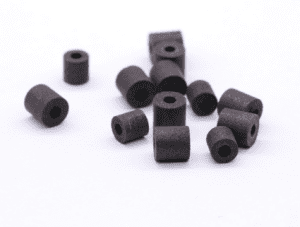

Electroplated deburring wheel

UB grinding wheels

Cylindrical parts (rod or shaft) finish grinding Before electroplated and after electroplated

Grinding discs for compressor