CBN (cubic boron nitride) grinding wheels are widely used in the automobile industry for grinding and shaping a variety of materials including hardened steels, cast iron, and superalloys. CBN is a synthetic material with a hardness and wear resistance similar to that of diamond, making it an excellent choice for grinding applications.

The automobile industry demands high precision and accuracy in the manufacturing of components, and CBN grinding wheels are well-suited to meet these requirements. They are able to maintain their shape and sharpness over long periods of use, resulting in consistent and repeatable grinding performance. This is important for achieving tight tolerances and smooth surface finishes. Vitrified bond CBN grinding wheel for crankshaft is also effective in reducing grinding time and increasing productivity, as they can operate at higher speeds and remove material more efficiently than traditional grinding wheels.

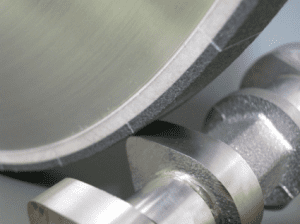

Cylindrical Vitrified bond CBN grinding wheels

Application: Crankshaft and Camshaft

Work-pieces material:

Cast iron: Chilled cast iron, nodular cast iron, grey cast iron, alloy cast iron,etc.

Steel: 20Cr, GCr15, CF53, 45# steel, 55# steel, 80B high carbon steel , etc.

Vitrified bond CBN grinding wheel for crankshafts due to their exceptional hardness, durability, and resistance to heat and wear. CBN stands for cubic boron nitride, which is a synthetic material that is second only to diamond in terms of hardness.

Crankshafts are typically made of steel, and their complex geometry and surface finish requirements make them challenging to grind accurately and efficiently. Vitrified bond CBN grinding wheels are well-suited for this application because they can maintain their shape and sharpness over long periods of use, which allows them to produce precise and consistent results.

Vitrified bond CBN grinding wheel for crankshaft offer several advantages over traditional grinding wheels in crankshaft grinding applications. These advantages include:

Vitrified bond CBN grinding wheel for crankshaft is made by mixing CBN grains with a ceramic binder and then sintering the mixture at high temperatures. The resulting wheel has a hard, dense structure that can withstand high grinding pressures and temperatures without deforming or breaking down.

When grinding crankshafts, it’s important to choose the right grit size, bond type, and wheel shape to achieve the desired surface finish and geometry. Vitrified bond CBN grinding wheel for crankshaft is available in a range of grit sizes and shapes to accommodate different crankshaft materials and grinding requirements.

Overall, vitrified bond CBN grinding wheel for crankshaft is a popular choice for grinding due to their superior performance and longevity.

|

Shape |

Diameter |

Thickness |

Working layer width |

|

1A1 |

100 ~ 750 mm |

10 ~ 70 mm |

3 ~ 10 mm |

|

3A1 |

100 ~ 750 mm |

10 ~ 70 mm |

3 ~ 10 mm |

|

9A1 |

350 ~ 750 mm |

20 ~ 70 mm |

3 ~ 10 mm |

|

14A1 |

100 ~ 750 mm |

10 ~ 70 mm |

3 ~ 10 mm |

| 9A1B | 100 ~ 400 mm | 10 ~ 30 mm | 3 ~ 10 mm |