Diamond grinding wheels require a harder material for dressing, such as a silicon carbide dressing stick or a diamond dressing tool.

Silicon carbide dressing sticks are made of a combination of silicon carbide abrasive and a bonding agent and are used to clean, true, and dress diamond and CBN grinding wheels. They are available in various shapes, sizes, and grits.

Diamond dressing tools, on the other hand, are typically made of a single diamond or a cluster of diamonds that are mounted in a shank or holder. They are used for the precision dressing of diamond and CBN grinding wheels and can be used to create specific wheel profiles.

It’s important to select the appropriate dressing tool for your specific grinding wheel and application and to follow the manufacturer’s recommendations for use and care of the tool.

![]()

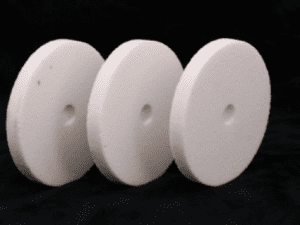

Our dressing wheels true the surface of a diamond or CBN grinding wheel by returning a wheel to its original round shape, removing burnt or compromised bond from the wheel, as well as to make a different profile on the diamond or CBN grinding wheel.

When choosing a dressing wheel, maybe it is better to speak with our expert staff, because if a dressing wheel is too soft or too hard, or the incorrect grit size, you may experience the following problems:

When using our dressing wheels our customers will see the following benefits:

|

Diamond and CBN grinding wheel |

Conventional Grinding Wheel |

|

Green Silicon Carbide wheel |

CVD needle dresser blade |

|

WA grinding wheel |

Needle dresser blade with natural diamond |

| Green Silicon Carbide Oil dressing Stick |

Single point dresser with natural diamond |

|

WA Oil dressing Stick |

Profile diamond, Ground |