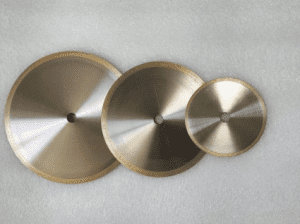

Diamond cut-off wheels are often used for cutting and shaping various materials, including optics. The use of diamond cut-off wheels in optics is particularly beneficial because diamond is one of the hardest materials on Earth, which allows for precise and efficient cutting.

In the manufacturing of optics, diamond cut-off wheels are typically used for cutting and shaping lenses and mirrors made of various materials, such as glass, quartz, and other crystals. The wheels are designed with a diamond-coated edge that allows for precise cuts, and they can be used on both curved and flat surfaces.

When using diamond cut-off wheels for optics, it is important to ensure that the wheels are properly aligned and that the cutting process is carefully monitored to avoid any damage to the material. Additionally, proper safety precautions should be taken when working with diamond cut-off wheels, as they can be hazardous if not used correctly.

Diamond cut-off wheels are often used for cutting and shaping optical glass because of their exceptional hardness and ability to make precise cuts. Optical glass is a specific type of glass that is used for producing high-quality lenses, mirrors, prisms, and other optical components.

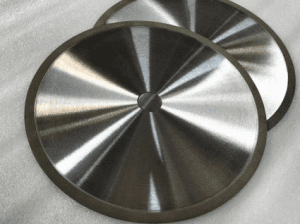

The diamond cut-off wheels used for cutting optical glass typically have a specialized diamond grit size and concentration that is optimized for this application. They may also have a special bonding matrix that allows for precise and efficient cutting while minimizing the risk of chipping or cracking the glass.

When using diamond cut-off wheels for optical glass, it is important to control the speed and pressure of the cutting process to prevent damage to the material. The cutting process may also need to be followed by polishing and/or lapping to achieve the desired surface finish.

Overall, diamond cut-off wheels are an important tool in the manufacturing of optical glass components, providing a precise and efficient method for shaping and cutting this specialized type of glass. However, proper training and safety precautions should be followed when using these tools to avoid any accidents or damage to the material.

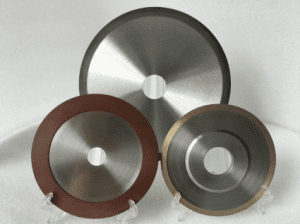

| Shape | Diameter | Thickness | Inner Hole | Grit |

| 1A1R | 50 | 0.2-4.0 mm | Depend on the Machine, please state when ordering | Please state the grit size for your application |

| 75 | ||||

| 100 | ||||

| 125 | ||||

| 150 | ||||

| 200 | ||||

| 250 | ||||

| 300 | ||||

| 350 | ||||

| 400 |