|

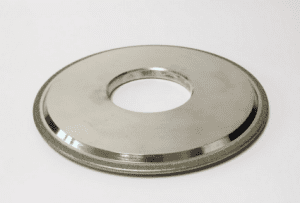

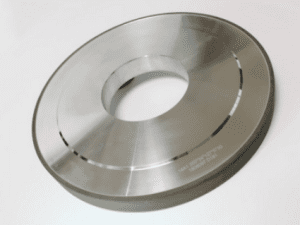

Electroplated diamond grinding wheel outside diameter |

350 mm |

|

Diamond grinding wheel bore diameter |

127 mm |

| Grinding wheel type for groove grinding |

Electroplated or metal bond

|

|

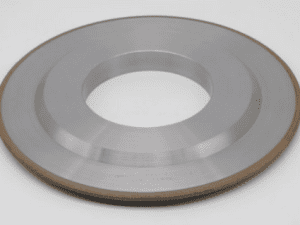

Grinding wheel type for the outside diameter grinding |

Resin bond |