| RNMN CBN Inserts | Insert Type | Size Info | ||||

| L(mm) | I.C(mm) | S(mm) | R(mm) | D(mm) | ||

| RNMN060400 | 6 | 6.35 | 4.76 | 0 | – | |

| RNMN120700 | 12 | 12. | 7.94 | 0 | – | |

| RNMN160700 | 16 | 16 | 7.94 | 0 | – | |

| RNMN190700 | 19 | 19.05 | 7.94 | 0 | – | |

| RNMN201000 | 20 | 20.000 | 10.00 | 0 | – | |

| RNMN251000 | 25 | 25.400 | 10.00 | 0 | – | |

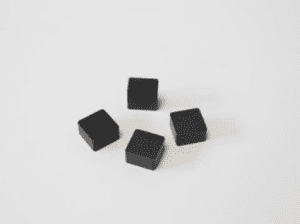

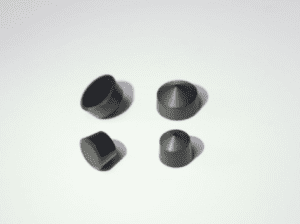

| RCGX Solid CBN

V |

Insert Type | Size Info | ||||

| L(mm) | I.C(mm) | S(mm) | R(mm) | D(mm) | ||

| RCGX060500 | 6.35 | 6.35 | 4.76 | – | – | |

| RCGX090700 | 9.525 | 9.525 | 7.94 | – | – | |

| RCGX120700 | 12.700 | 12.700 | 7.94 | – | – | |

| RCGX151000 | 15.875 | 15.875 | 10.0 | – | – | |

| RCGX191000 | 19.05 | 19.05 | 10.0 | – | – | |

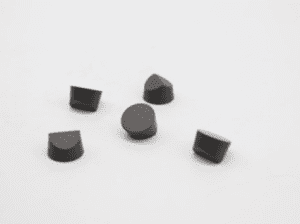

| SNMN Solid PCBN Inserts | Insert Type | Size Info | ||||

| L(mm) | I.C(mm) | S(mm) | R(mm) | D(mm) | ||

| SNMN090308 | 9.520 | 9.525 | 3.18 | – | – | |

| SNMN090412 | 9.525 | 9.525 | 4.76 | – | – | |

| SNMN120712 | 12.700 | 12.700 | 7.94 | – | – | |

| SNMN150704 | 15.875 | 15.875 | 7.94 | – | – | |

| SNMN150708 | 15.875 | 15.875 | 7.94 | – | – | |

| SNMN201020 | 20 | 20 | 10 | – | – | |