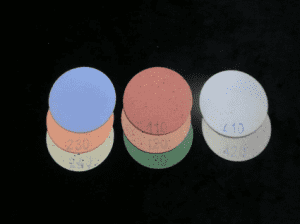

| Pad Type | Filler | Average Density g/cm³ (lb/ft³) | Average Hardness (Shore A) |

Application |

| HC-110 | Cerium Oxide | 0.42 (26) | 78 | Glass, Crystal, Metal, Ceramic |

| HC-120 | Cerium Oxide | 0.43 (27) | 78 | Glass, Crystal |

| HC-130 | Cerium Oxide | 0.35 (22) | 66 | Glass, Crystal |

| HC-210 | Zirconium Oxide | 0.59 (37) | 90 | Glass, Ceramic |

| HC-230 | Zirconium Oxide | 0.40 (25) | 74 | Glass, Crystal |

| HC-240 | Zirconium Oxide | 0.57 (36) | 88 | Precision Optics |

| HC-410 | None | 0.51 (32) | 88 | Glass, Crystal, Metal, Ceramic |

| HC-420 | None | 0.78 (49) | 96 | Glass, Crystal, Precision Optics |