What is thermal Spray Coating?

Thermal spraying coating is a technology that improves or restores the surface of a solid material. The process can be used to apply coatings to a wide range of materials and components, to provide resistance to Wear, erosion, cavitation, corrosion, abrasion, or heat. Thermal spraying is also used to provide electrical conductivity or insulation, lubricity, high or low friction, sacrificial wear, chemical resistance, and many other desirable surface properties.

Thermal spraying coating is widely adopted across many industries as a preferred method. It has huge scope to extend the life of new components or through the use of tried and tested techniques, to repair and re-engineer worn or damaged components.

Diamond Grinding wheels have many applications in the thermal spray coating industry:

A few common applications are:

Reclamation and re-engineering of a wide range of rotating and moving parts from machines of all kinds, including Road and rail vehicles, ships, aircraft, pumps, valves, printing presses, electric motors,

paper-making machines, chemical plants, food machinery, mining and quarrying machinery, earth-movers, machine tools, power generation and aerospace turbine repair, landing gear (chrome replacement), and virtually any equipment which is subject to wear, erosion or corrosion. This is done using arc spray, flame spray, or HVOF systems to spray steels, nickel alloys, carbides, stainless alloys, bronzes, copper, and many other materials.

New components which benefit from the enhanced surface properties that thermal spraying provides include Gate and ball valves, rock drilling bits, and downhole tools for the oil and gas and petrochemicals industry, hydraulic piston rods, print rollers, fluid seals, aerospace combustion chambers, turbine blades.

Thermal-sprayed coatings are used on a vast range of components that operate in adverse environments where, erosion, wear, corrosion or heat, conspire to reduce component life. Component life is significantly prolonged by using arc, flame, plasma, or HVOF systems to apply metals, ceramics, and carbides.

Please leave a message on our website: www.honestsuperabrasives.com

|

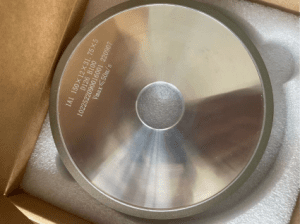

Cylindrical Diamond Grinding wheel |

Vitrified |

Resin |

Metal |

|

|

Internal Diamond Grinding wheel |

||||

|

Surface grinding wheels for surface grinder |

Conventional Grinding wheel |

Super Abrasives wheel |

||

|

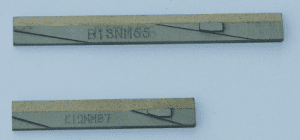

Diamond oil honing stone for precision hole |

Metal bond |

|||

|

Diamond film belts for super finishing |

Polyester Film backing |

|||

|

Electroplated diamond belt for polishing |

Electroplated bond |

|||

|

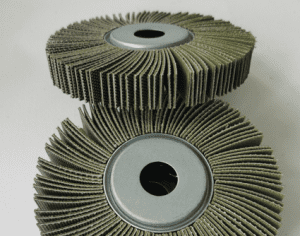

Diamond flap grinding wheels for polishing |

Electroplated bond |

|||

|

Diamond Hand Pad |

Electroplated bond |

|||