|

When placing an order, please also inform us some information: |

|

|

Work-pieces |

Drawing |

|

Material |

|

|

Surface finish require |

|

|

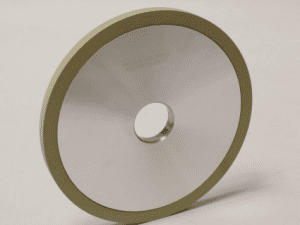

Grinding wheel |

Dimension |

|

Specification |

|

|

Manufacture |

|

|

Machine |

Manufacture |

|

Mode/Type |

|

|

Coolant |

|