| Work-pieces | Material | Machine | Shape | Coolant |

| Drills

End mills Reamer |

Tungsten carbide

HSS Cermet |

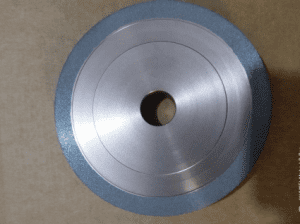

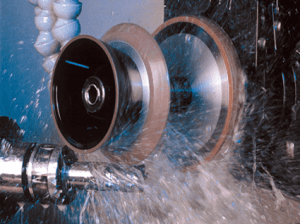

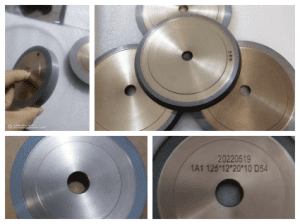

All CNC tool grinding machines | 1A1, 1V1, 14F1

Diameter: 50 – 200 mm T: 3 – 30 mm X: 5 – 15 mm |

Oil

Emulsion |

| Micro drills

Mini end mills Burrs |

Tungsten carbide

HSS |

Precision tool grinding machines for micro and mini tools | 3A1, 4A9, 14V1

Diameter: 50 – 200 mm U: 2 – 6 mm X: 5 – 10 mm |