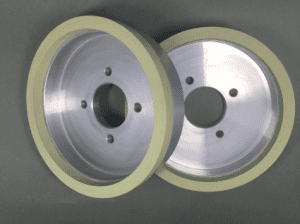

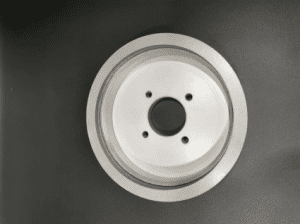

| Shape | D | T | H | W | X |

| 6A2H | 150 | 40 | 40 | 3 | 5 |

| 150 | 40 | 40 | 3 | 10 | |

| 150 | 40 | 40 | 5 | 5 | |

| 150 | 40 | 40 | 5 | 10 | |

| 150 | 40 | 40 | 10 | 5 | |

| 150 | 40 | 40 | 10 | 10 | |

| 150 | 40 | 40 | 15 | 5 | |

| 150 | 40 | 40 | 15 | 10 | |

| 150 | 40 | 40 | 20 | 5 | |

| 150 | 40 | 40 | 20 | 10 | |

| 200 | 40 | 40 | 5 | 6 | |

| 200 | 40 | 40 | 10 | 6 | |

| 200 | 40 | 40 | 10 | 10 | |

| 200 | 40 | 40 | 20 | 6 | |

| 200 | 40 | 40 | 20 | 10 | |

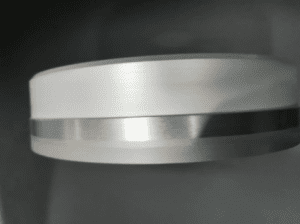

| 2A2T | 350 | 45 | 310 | 5 | 10 |

| 350 | 45 | 310 | 10 | 10 | |

| 350 | 45 | 310 | 15 | 10 | |

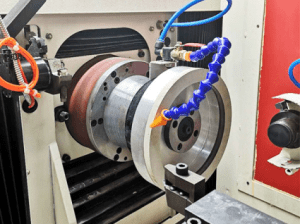

| 11A2H | 400 | 38 | 355 | 5 | 10 |

| 400 | 38 | 355 | 10 | 10 | |

| 400 | 38 | 355 | 15 | 10 |