Hong Cheng has over 10 years of Diamond&CBN grinding wheels engineering experience in the wood industry, but that does not mean we stop looking for new solutions for our wood customers.

Super abrasive grinding wheels, which are typically made with diamond or cubic boron nitride (CBN), are commonly used in the woodworking industry for applications such as sharpening tools and grinding and polishing wood surfaces.

Diamond grinding wheels are particularly effective at grinding and sharpening carbide and other hard materials commonly used in woodworking, such as saw blades and drill bits.

CBN wheels, on the other hand, are often used for grinding high-speed steel and other materials that are difficult to grind with conventional abrasives.

One of the advantages of using Diamond&CBN grinding wheels in woodworking is their ability to maintain their shape and sharpness for longer periods of time compared to traditional abrasive wheels. This means that they can produce consistent results over a longer period of time, reducing the need for frequent wheel changes and increasing productivity.

Diamond&CBN grinding wheels also generate less heat during the grinding process, which can be beneficial for reducing the risk of burning the wood or damaging the tool being sharpened. Additionally, they can produce a finer surface finish compared to conventional abrasive wheels, which can be important for certain woodworking applications.

Products Application:

Top Grinding

Face Grinding

Side Grinding

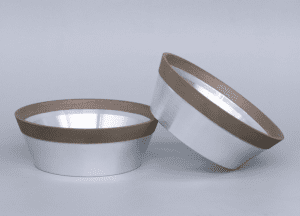

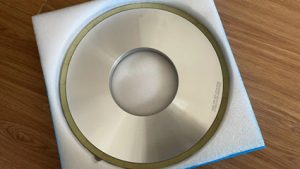

Available Shape:

1A1,1F1, 3A1,3F1, 4A2, 4BT9, 6A2, 6A9, 11A2,12A2, 12V9, 14A1, 14F1, 15V9

Resin bond type has the features of good self-sharpening, sharp cutting, high efficiency, low roughness of workpiece surface, little heat generating, and without burning the workpiece. It is suitable for high efficiency and precision grinding of most workpieces.

Electroplated bond CBN grinding wheels for band saw blades. The popular band saw brands: Wood Mizer, MILL, SIMOND, WINTERSTEICER, etc.

Vitrified bond has higher hardness, it is more suitable for grinding PCD tips circle saw blade.

Our customers use our solutions for grinding HSS, cermet, carbide, PCD products, and more.

The suitable machine includes Vollmer, Akemat, Woodtronic, and Widam.

We are especially proud of our reputation in the wood industry for quality and reliability and have always taken pride in helping our customers with finding the right grinding solution.

Overall, super abrasive grinding wheels offer a number of advantages for woodworking applications, including longer tool life, improved productivity, and better surface finishes.

|

Shape |

Diameter

(mm) |

Layer width (mm) | Layer thickness (mm) |

Inner Hole (mm) |

|

1A1W |

5/5.5/6.0/6.5 | 1.5 | 3.0 | On request |

|

4A2 |

75/100/125/150 | 5/6/10 |

2/3/5/10 |

|

|

4BT9 |

75/100/125/150 |

|

||

| 6A2 | 75/100/125/150 | 5/6/10 |

2/3/5/10 |

|

|

6A9 |

75/100/125/150 | 5/6/10 |

2/3/5/10 |

|

|

12V2 |

75/100/125/150 | 5/6/10 | 2/3/5/10 | |

|

12V9 |

75/100/125/150 | 5/6/10 |

2/3/5/10 |

|

| 14F1 | 75/100/125/150 | 5/6/10 |

2/3/5/10 |

|

|

15V9 |

75/100/125/150 | 5/6/10 |

2/3/5/10 |