| Shape | Diameter (mm) | Layer width (mm) | Layer thickness (mm) | Inner Hole (mm) |

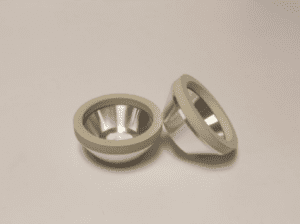

| 4A2 | 75/100/125/150 | 5/10 | 3/5/10 | On request |

| 6A2 | 75/100/125/150 | 5/10 | 3/5/10 | |

| 6A9 | 75/100/125/150 | 5/10 | 3/5/10 | |

| 11A2 | 75/100/125/150 | 5/10 | 3/5/10 | |

| 12A9 | 75/100/125/150 | 5/10 | 3/5/10 | |

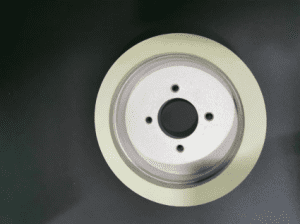

| 14A1 | 75/100/125/150 | 5/10 | 3/5/10 |