| Operation: External grinding |

| Work-piece: Roll Diameter 120—1000 mm, Length 1.5—10 m |

| Material: HVOF spraying tungsten carbide or ceramic coating on a steel body |

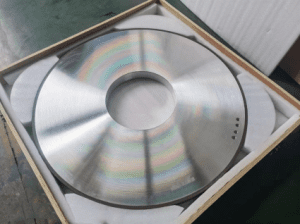

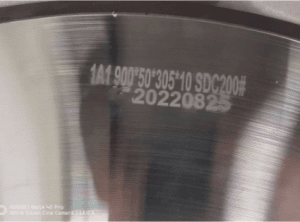

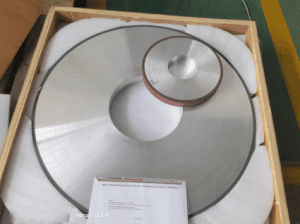

| Diamond wheel specification: 1A1 D900*T50*H304.8*X10 mm SDC200# |

| Dressing white aluminum oxide |

| Machine: External grinding machine |

| Coolant: Emulsion, Pressure: >/= 3 Bar |