Surface roughness

Surface roughness refers to the irregularities or variations in the texture of a surface. It is a measure of how uneven or bumpy a surface is at a microscopic level. Surface roughness can be quantified using different parameters, such as Ra (arithmetical average roughness), Rz (average maximum height), Rq (root mean square roughness), and Rt (total roughness).

Surface roughness is typically measured by using instruments called profilometers or surface roughness testers. These devices move a stylus or a laser probe along the surface and record the vertical deviations from the mean surface. The collected data is then used to calculate the surface roughness parameters.

The roughness of a surface can have significant implications in various industries and applications. For example:

Manufacturing: Surface roughness is critical in manufacturing processes where parts need to fit together or move smoothly. It affects the performance, durability, and functionality of components. For example, in automotive engineering, the surface finish of engine components can impact fuel efficiency and wear characteristics.

Tribology: Surface roughness plays a crucial role in tribological interactions, such as friction, wear, and lubrication. Rough surfaces have increased frictional resistance and may experience accelerated wear compared to smoother surfaces. Controlling surface roughness is important in optimizing performance and extending the lifespan of mechanical systems.

Optics: In optical systems, surface roughness affects light scattering, reflection, and transmission properties. For high-precision optics like lenses, mirrors, or optical coatings, minimizing surface roughness is crucial to reduce light loss and maintain image quality.

Biomaterials: Surface roughness is a significant factor in biomaterials and biomedical applications. Implants, prosthetics, and medical devices need to have appropriate surface roughness to facilitate cell adhesion, tissue growth, and integration with the body.

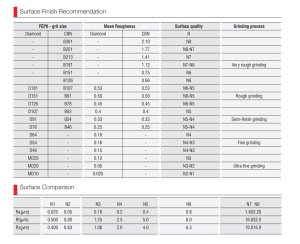

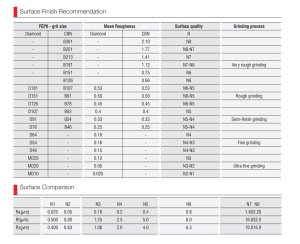

Controlling and measuring surface roughness is essential to ensure product quality and performance in various industries. Surface finishing techniques like polishing, grinding, lapping, and coatings can be employed to achieve the desired level of roughness for specific applications.