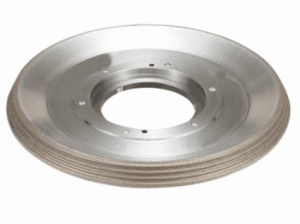

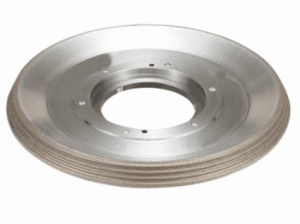

Electroplated bond grinding wheels

High precision

Stable quality

Fast delivery time

Good after sales service

Electroplated bond grinding wheels

Electroplated bond grinding wheels are specialized tools used in various industries for precision grinding applications. The electroplated bond refers to a single layer of abrasive grains that are firmly bonded to the wheel’s surface using a metal plating process. This bond type offers several advantages, including high precision, excellent retention of abrasive grains, and the ability to produce intricate wheels designs. Here are some common applications of electroplated bond grinding wheels:

1. Tool and Die Making: Electroplated bond grinding wheels are extensively used in tool and die making industries for precision grinding, shaping, and finishing of various materials such as hardened steels, carbide, ceramics, and other hard alloys. They are suitable for applications like tool sharpening, grinding of complex profiles, and finishing of punches and dies.

2. Optical Industry: Electroplated bond grinding wheels are widely used in the optical industry for manufacturing lenses, prisms, and other precision optical components. These wheels can grind and shape optical glasses, crystals, and other materials with high accuracy, ensuring precise surface finishes and geometries required for optical applications.

3. Aerospace Industry: In the aerospace industry, electroplated bond grinding wheels find applications in the grinding and finishing of turbine blades, engine components, and other high-precision parts. The wheels can effectively remove material, maintain tight tolerances, and achieve superior surface finishes critical for aerospace applications.

4. Medical Industry: Electroplated bond grinding wheels are employed in the medical field for manufacturing surgical instruments, dental tools, and other medical devices. They can grind and shape materials like stainless steel, titanium, and various biocompatible alloys with high precision, meeting the stringent requirements of the medical industry.

5. Electronics Industry: Electroplated bond grinding wheels are used in the fabrication of electronic components like semiconductors, printed circuit boards (PCBs), and magnetic heads. They are capable of grinding and thinning materials such as silicon wafers, ceramics, and hard metals, ensuring precise dimensions and surface quality needed for electronic applications.

6. Automotive Industry: Electroplated bond grinding wheels are utilized in the automotive sector for grinding and finishing engine components, transmission parts, and other critical automotive parts. They help achieve high dimensional accuracy, tight tolerances, and excellent surface finishes, contributing to the overall quality and performance of automotive components.

Overall, electroplated bond grinding wheels are versatile tools that find applications in numerous industries requiring precision grinding and finishing operations. They offer high efficiency, accuracy, and surface quality, making them suitable for a wide range of materials and applications.