Metal bond grinding wheel for float Glass

Metal bond grinding wheel for Automobile Glass

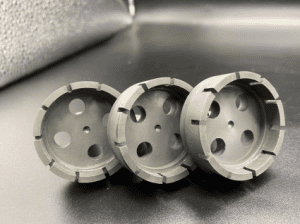

Metal bond edge grinding wheel for wafer

Metal bond drill bit for glass

Metal bond drill bit for optics

Metal bond grinding wheel for roll industry

Metal bond grinding wheel for ingot

Metal bond cut-off wheels for glass

Metal bond cut-off wheels for Metallographic

Metal bond honing stone for precision hole

Metal bond grinding wheel for inserts

Metal bond grinding wheels for reamer

Metal bond grinding wheels for ceramic

Metal bond grinding wheels for mills

Metal bond grinding wheels for ruby

Metal bond grinding wheels for sapphire