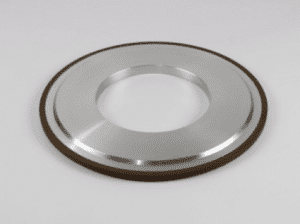

High-quality Resin bond grinding wheels

High-quality OD resin bond grinding wheels

High-quality Surface resin bond grinding wheels

High-quality Cylindrical resin bond grinding wheels

Resin bond cylindrical diamond grinding wheel for tungsten carbide

Resin bond cylindrical diamond grinding wheel for carbide coating

Resin bond cylindrical diamond grinding wheel for ceramic coating

Resin bond cylindrical diamond grinding wheel for HVOF coating

Resin bond cylindrical diamond grinding wheel for thermal spray coating