High quality Resin bond grinding wheels

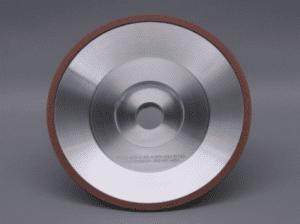

High quality OD resin bond grinding wheels

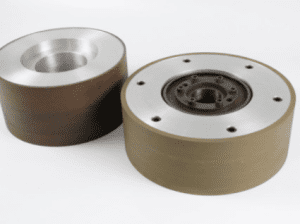

High quality ID resin bond grinding wheels

High quality Surface resin bond grinding wheels

High quality Cylindrical resin bond grinding wheels

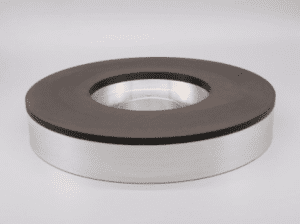

High quality Centerless resin bond grinding wheels