| Working | Working | Layer | Length | |||||||

| Code | 38 | 51 | 64 | 76 | 89 | 102 | ||||

| Code | mm | 0.380-0.510 | 0.510-0.640 | 0.640-0.760 | 0.76-0.890 | 0.890-1.020 | 1.020-1.150 | |||

| 15 | 0.015-0.020 | 1538 | 1551 | |||||||

| 20 | 0.020-0.025 | 2038 | 2051 | 2064 | 2576 | |||||

| Layer | 25 | 0.025-0.030 | 2538 | 2551 | 2564 | 3076 | ||||

| 30 | 0.030-0.035 | 3038 | 3051 | 3064 | 3576 | 3089 | ||||

| 35 | 0.035-0.040 | 3538 | 3551 | 3564 | 4076 | 3589 | 35102 | |||

| 40 | 0.040-0.045 | 4038 | 4051 | 4064 | 4576 | 4089 | 40102 | |||

| 45 | 0.045-0.050 | 4538 | 4551 | 4564 | 5076 | 4589 | 45102 | |||

| 50 | 0.050-0.055 | 5038 | 5051 | 5064 | 5576 | 5089 | 50102 | |||

| Width | 55 | 0.055-0.060 | 5538 | 5551 | 5564 | 6076 | 5589 | 55102 | ||

| 60 | 0.060-0.070 | 6051 | 6064 | 7076 | 6089 | 60102 | ||||

| 70 | 0.070-0.080 | 7064 | 8076 | 7089 | 70105 | |||||

| 80 | 0.080-0.090 | 8089 | 80102 | |||||||

| 90 | 0.090-0.100 | 9089 | 90102 | |||||||

| 100 | 0.100-0.110 | 100102 | ||||||||

| Working | Layer | Length | ||||||||

| Working | Code | 115 | 128 | 141 | 154 | 167 | ||||

| Code | mm | 1.150-1.280 | 1.280-1.410 | 1.410-1.540 | 1.540-1.670 | 1.670-1.800 | ||||

| 15 | ||||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| Layer | 30 | |||||||||

| 35 | ||||||||||

| 40 | 40115 | |||||||||

| 45 | 45115 | 45128 | ||||||||

| 50 | 50115 | 50128 | 50141 | |||||||

| 55 | 55115 | 55128 | 55141 | 55154 | ||||||

| Width | 60 | 60115 | 60128 | 60141 | 60154 | 60167 | ||||

| 70 | 70115 | 70128 | 70141 | 70154 | 70167 | |||||

| 80 | 80115 | 80128 | 80141 | 80154 | 80167 | |||||

| 90 | 90115 | 90128 | 90114 | 90154 | 90167 | |||||

| 100 | 100115 | 100128 | 100141 | 100154 | 100167 | |||||

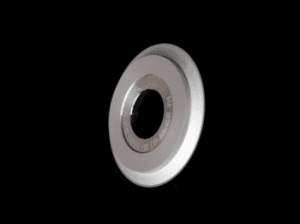

| H1 | 13 | D | M | 15 | 38 | ||

| Out Diameter 55.56 mm | Grit(um) | Concentration | Hardness | Width | Length | ||

| Inner Diameter 19.05 mm | 13 | 1-3 | A | Lowest | S: soft | ||

| 24 | 2-4 | B | Lower | ||||

| 25 | 2-5 | C | Low | M:standard | |||

| 26 | 2-6 | D | Standard | ||||

| 35 | 3-5 | E | High | ||||

| 36 | 3-6 | F | Higher | ||||

| 46 | 4-6 | ||||||

| 48 | 4-8 | ||||||

| 57 | 5-7 | ||||||